I do. My dad was not happy because I stripped it trying to take it out. Fortunately we finagled it out, but it was ugly.

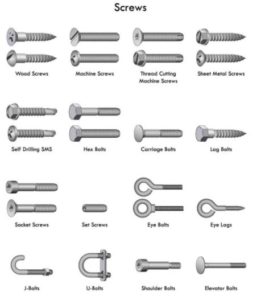

When it comes to screws, there are a lot of different types of screws as well as an intricate set of parts to a screw. We dug in and decided to write an epic guide on screw options. Here it is.

I. Screwhead Buying Guide

Chart showing 60 types of screws, screw heads, bolts, nuts and washers chart

Types of Screw Table

|

|

|

|

Finding the right type of screw head for your project when there are hundreds of combinations of the drive type and head shape can be confusing, especially for beginning DIYers.

It’s important to understand the differences between the shapes and drive types, not only so that you can find the right tools for your screws, but also so that you can ensure that your screwhead does everything you need for your project.

First, let’s focus on what it means for a screw to be countersunk or non-countersunk, and learn about the different types of screwheads for each.

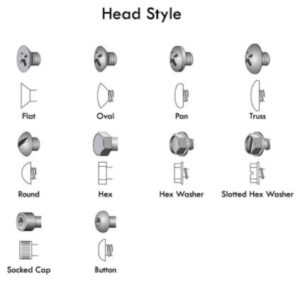

II. Screw head Shapes

The shape of your screwhead may not seem important, but each head type is made that way for a reason, usually enabling you to create your project easier, and with your preferred finish.

The head of a screw is where your screw will stop. Only the threaded part will be beneath the surface of your project, leaving the head outside, or flush with, the surface.

Some head shapes help to create the look of the finished product, but they also usually have a purpose beyond aesthetics. The head shape of the screw also helps you drive the screw into your material using your force and the mechanics of the screw.

III. Types of Screw heads

A. Countersunk Screw Heads

Countersinking is a method used to help prevent splitting wood when you drill.

With the use of a countersinking bit, you can create both a pilot hold and the proper angle needed to house your screw.

The process pre-drills your hole with the correct head angle to help create a professional-looking finish for your project.

Some screwheads require countersinking because of their shape and angle. Here are the head shapes you’ll need to countersink before drilling:

1. Flat

Flat screwheads sit entirely flush with a surface, leaving none of the head exposed. These types of screws require you to countersink them.

The benefit of flat screws is that you won’t have to worry about your screw sticking out from the surface and causing other things to catch on it, which is essential if you’re creating your own sofa or building a bookshelf that people will walk by often.

You also won’t see the screw head if you use a screw cover.

Flat Head Degrees

Flat head screws have varying degrees. The degree of a flat head refers to its had angle or the angle from the top of the head to the surface where the threaded part meets the head.

An 82-degree flat head is the standard angle, but there are also 90-degrees, 100-degrees, and more. A higher degree requires a shorter, but more spread out, countersink hole.

Flat Undercut 82-degree

A flat undercut 82-degree head has the same angle as a standard 82-degree head, but the head is much shorter. This head shape helps give the screw a longer thread on the same screw length because of its shorter head size.

2. Raised

Raised heads, sometimes known as oval-shaped heads, have an angle much like flat screws but have more of a dome-shaped head. You’ll also need to countersink these screws to accommodate the angle.

Unlike a flat screw, the head of a raised screw will come out of the surface slightly. This shape doesn’t necessarily help the screw’s drive performance, but it, instead, is more for decoration.

3. Bugle

Bugle heads are used mainly on screws made for plasterboard and drywall.

This shape is much like a flat screw head, except that, instead of an angle underneath the surface of the head, you’ll see a curved shape that can reduce damage to a surface.

Bugle screws are self-drilling, so you won’t need to drill any pilot holes before using them, and their unique shape allows them to distribute stress over a wider surface than flat screws.

B. Non-Countersunk Screw Heads

Non-countersunk screws tend to have a head shape without an angle, and one that sits outside of the surface of your project, so it’s not necessary to create an angle that houses the screw head.

Here are the most common types of heads that won’t require you to countersink them:

1. Binding

Binding screws are a unique type of screw that you can use for a range of projects. These screws have a slightly domed head and screw into each other with a male and female side.

Often, short binding screws can hold together large manuals and other bookbinding projects, but you can also use them to hold together swatches, leather, and more.

2. Domed

Domed heads are one of the most common types you’ll find. These are ideal for projects that don’t require you to hide the head of the screw like you would with a flat head, such as with an ottoman using decorative screws that protrude from the fabric.

The dome shape creates a visually appealing design on the surface, while the flat inner part of the dome helps the screw stop where it needs to just at the surface.

3. Flange

Flange screws are sometimes referred to as frame screws.

The head of these screws can vary from circular to hexed, and it juts out from a circular flange directly underneath the head.

The flange helps the screw to remain in its position, taking the place of a washer for some projects.

4. Truss

Truss heads are typically wider than the heads on other screws and have a slightly rounded surface.

You’ll usually need truss heads when working with sheet metal and other projects that require large holes because the wide head prevents the truss screw from going through the hole.

C. Combination Heads

Although these are the more common types of heads for screws, it’s possible to find variations and combinations of them.

It’s important to pay attention to whether the screws need to be countersunk or not. You can always find this out by looking at the head.

A screwhead that requires countersinking will have an angular shape underneath the head, while a screw that doesn’t need countersinking will be flat under the head.

Your project is also something to take into consideration. Do you mind if a rounded head protrudes from the surface, or would you rather have a smooth finish from a flat screw?

It’s possible that you’ll find a combination of screwheads that will meet your needs, as long as you understand how each one will affect your project’s assembly and finished look.

D. Screwhead Drive Types

The drive of a screwhead refers to the type of tool you’ll need to install the screw. You’ll notice several different shapes on screws, in addition to their type of head, that will require a special type of screwdriver to work with the screw.

The drive is directly related to how the screw attaches to a surface. Some drives are better at avoiding stripping, which renders a screw useless, than others, but may also cost more money and be more difficult to find tools for.

1. Hex External

External hex screws have a hexagonal head shape that protrudes from the surface. Some have built-in flanges, whereas others only have the hexagon shape as the full head.

You’ll need a wrench or socket to install or remove these screws. You can get good leverage on these screws since you turn the full head, rather than just an internal portion of the head.

2. Hex Internal

An internal hex screw requires an Allen wrench to install or remove.

These screws are common for furniture that requires some assembly because they’re unlikely to be damaged by the Allen wrench when installing, unlike a Phillips or slotted screw, leaving you with a pleasing finish.

Most internal hex screws come with an Allen wrench that fits them.

3. Phillips

A Phillips screw is one of the most common. This screw has a cross-shape that helps self-center the screw to avoid it drilling at odd angles.

You can also use a drill with a Phillips screw because its self-centering design allows it to remain in place when you apply force from a drill. However, too much force can strip the head quickly.

4. Pozidrive

Pizodrive screws look similar to the Phillips shape, except that they have a few more grooves in them that create a shape resembling a star.

You can sometimes use a Phillips screwdriver to remove them, but not always.

These screws give slightly more stability when force is applied than Phillips screws, but you’ll need a specific bit or screwdriver to match the grooves.

You can tell the difference between a Pozidrive and Phillips screw by looking at them from the side. On the Pozidrive, you’ll notice ribs between each of the four arms, and they’ll be marked with a “pz.”

5. Quadrex

The Quadrex head drive, also known as a Phillips square drive, is a combination of Phillips and square recess.

It looks much like the Phillips design, except that the middle of the cross shape is squared rather than pointed, which can help prevent stripping when you apply more force.

6. Slotted

Slotted head screws are what most people refer to as flathead screws, because they have one narrow opening for a flat screwdriver.

Although this type of screw is one of the most common and inexpensive types, it’s also the most prone to stripping. In fact, slotted screws are supposed to strip, by design, to prevent you from overtightening them.

Slotted screws are best for projects that require a few screws that you can screw manually, rather than with a powered drill, which will often cause the screw to strip or cam out.

7. Square Recess

Square recess screws are also commonly referred to as Robertsons.

These have a square center point that prevents cam outs. The bit that drives square recess screws also juts out on a square taper, which creates a self-holding design so that you don’t need to hold the bit in place.

8. Star

Star-shaped heads encompass several different styles that form shapes that resemble stars.

The double-square drive has two Robertson’s squares that form an 8-point star in the middle. You can use a Robertson’s bit to drive it or use a special one for the double-square for higher torque application.

There’s also a triple square with three Robertson’s squares, creating a 12-point star.

Triple squares are most commonly used when you need a high level of force without stripping the screw. You’ll see them mostly on internal car parts, like drivetrain components.

9. TORX

Most people have TORX screw bits in their drill bit sets but rarely use them.

TORX screws have a 6-point star shape in the middle and are often used on electronics items, like computers and DVD players.

One of the reasons these screws are becoming more popular in recent years is because of their ability to prevent cam out, which is especially helpful when building electronics.

10. TORX Plus

TORX Plus screws have shallower grooves between the star points to allow a screwdriver or bit to have more contact with the screwhead, which will enable you to put more force on it.

11. Tri-Wing

Tri-Wing screws are a somewhat recent invention of the Phillips Screw Company, which offer both the ability to apply more force than you could to a regular Phillips screw and more security than other screws.

The Tri-Wing design needs a special driver to install and remove it, and its deep grooves allow for more torque from a drill.

E. Tamper-Resistant Screws

If you find a screw that looks a bit differently than the type it says it is, then it’s probably a tamper-resistant version.

Tamper-resistant screws are variations of some of the most common types, such as TORX, Phillips, and Hex.

These screws are beneficial for use in public places that might fall victim to theft, like public restrooms, where expensive fixtures can be tempting for some.

There are various types of tamper-resistant screws, all of which offer multiple levels of security:

1. Pin Screws

The most common type of tamper-resistant screw, the pin screw will have the same design as what their regular versions have, such as a cross-shape for a Phillips screw, but with an additional layer of security to prevent easy removal.

Each head will have an additional pin in the design that requires a special tool to install and remove them. A Phillips screwdriver will not work to install or remove a tamper-resistant Phillips screw.

2. Sentinel Screws

Sentinel screws offer high-level protection because you can only drive them one way. They’re challenging to remove, so they’re best for permanent fixtures.

3. 2-Hole Screws

2-hole screws, also known as spanners, offer security without sacrificing the finished look. They have a flat head with two small holes that require a special tool to install and remove them.

F. More Details

There are a few more important things to note about different screwheads before you make a purchase:

1. Avoiding Cam-Out

We mentioned that quite a few screws are designed to prevent cam outs, while the makers of the slotted screw specifically designed it to cam out to stop the screw from overtightening.

Cam out is something you don’t want to happen to you during your project.

When a screw cams out, your screwdriver or bit slips out of the screw head. When this happens, it can:

- Strip a screw head, rendering the screw useless

- Cause the wood you’re drilling into to split

- Cause damage to other material with nicks, cracks, and more

- Cause injury to the user

Screws that can handle more torque, or force, will typically be less likely to cam out. Screwheads with several grooves, such as the TORX and other star-shaped heads, give your tools more points and grooves to hold onto, lowering the risk of a cam out.

Selecting the right bit for your screw is essential to avoiding cam out. This helpful video can show you how to choose the right bit for your screw head:

2. Preventing Stripped Screws

The most important thing you can do to avoid your screws from stripping is to use the right drill bit and make sure it’s a good one.

A cheap drill bit may save you a few dollars, but if it’s wasting all of your screws, it’s not doing you much good in the long run.

However, the wrong size bit can also be to blame. A bit that’s slightly too small or large can both have the same effect on your screws: a stripped head.

It’s also crucial that you don’t angle your bit in a way that makes the bit turn incorrectly. It’s easy to prevent this with certain screw heads, like TORX, but it’s not so easy for more simplified heads, like Phillips and slotted.

3. Removing Stripped Screws

If your screw heads do strip out, they’ll become damaged to the point that your regular tools won’t be able to install them further or remove them.

If you’re trying to install a screw with a stripped head, don’t. Remove the screw and start with a new one.

Removing the screw can be tricky if it’s entirely installed, though, unless you have a special tool known as a stripped screw extractor.

Sometimes, this special bit comes in a kit with other tools, all of which work together to grab and pull out the stripped screw.

This video demonstrates how to use an extractor to remove a stripped screw, as well as a couple of other handy methods to tuck in your back pocket:

4. Matching Screwheads to Materials and Projects

There’s no point spending more money on a screw and matching bit that you don’t need for your project.

Small woodworking projects that don’t require extra force from a drill are ones that you can usually complete with a Phillips, slotted, or other simplified screw head.

A good rule of thumb is to go for a more simplified design with any project that needs only a light force from a drill or manual use of a screwdriver.

For more complicated projects with heavy-duty materials, just as installing sheetrock or assembling car parts, you’ll want a screw head with a design that has several points and grooves, such as a TORX or Twi-Wing screw.

5. Screw Head Material

The screw head material will almost always match the material of the threaded part of a screw.

But, different materials can make a big difference in your project, depending on the materials you’re working with.

Most screws consist of steel but may also come in variations that are more weather-resistant than regular steel, like stainless steel or titanium. These are good options for putting together outdoor furniture or anything that will be exposed to weather or damp conditions.

You might also find aluminum screws, which can be a good option for projects that won’t be exposed to weather conditions. Aluminum can corrode quickly and is less durable than steel and other heavy-duty materials.

If you’re going to use a drill with your screws, you might also want to opt for a more durable material, since aluminum can strip more easily with higher force from a drill.

6. Price Differences

Most common screws are relatively low in price. It’s when you need to look for screws in odd sizes that you might start seeing a large spike in their cost. Also, specialty screws, like drywall screws, will typically cost more than screws meant for generic purposes.

The screw head does make a difference, too, in most cases. More common heads, like slotted and Phillips are generally at the low end of the budget, whereas star-shaped, TORX and other high-performing screws may cost more.

However, they’ll also save you some hassle when assembling your project, since you’ll have less worry over cam out and stripping with high-performing screws.

G. Where to Buy Screws Online

Now you’re aware of the many types of screwheads and how they can assist you with your project. If you’re considering buying screws online, we recommend the following retailers, which offer a wide selection of screws and heads to meet your needs: